Surface Finishing

At Alinox Verona, we supply products with different types of surface finishes. Such requests are usually tied to the specific conditions under which the component will be used.

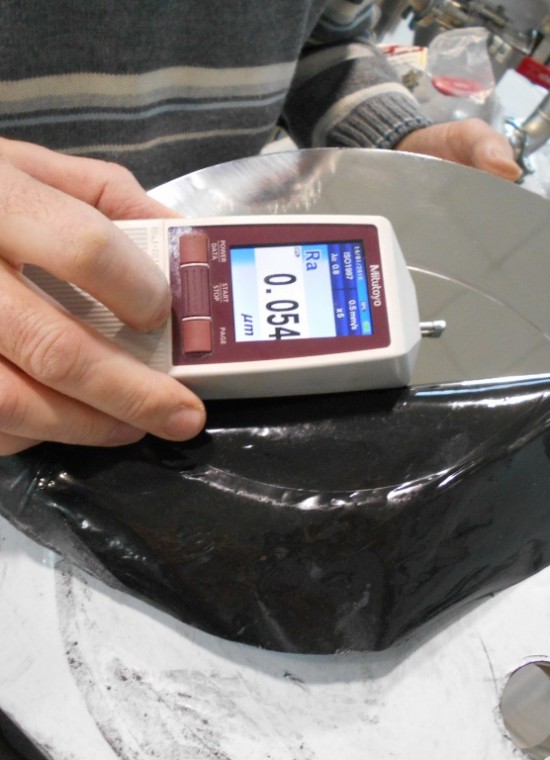

| Polishing | This process reduces roughness, prevents contamination and stagnation in interstices. The roughness is measured and certified. This is fundamental for systems destined for the pharmaceutical sector and reactors for biotechnology. |

| Shot Peening | This mechanical process involves striking a surface with small ceramic balls, lending the part a slightly opaque but bright, uniform appearance. |

|

Circle polishing |

This geometric pattern is created via circular grinding. It is largely used for vessels and tanks in the food sector. |

| Satin Finish |

Created via abrasion in one direction, it is glossy and uniform. It is used on framework and tanks. |

| 2B Pickled | This is the most common in industry. Slightly shiny, it is suitable where a special finish is not required. The welds are cleaned by pickling. |